In the world of 3D printing, filament choice matters, and with so many brands available, it’s easy to default to well-known names like Polymaker or eSUN. But if you’re looking to reduce your footprint and support sustainable innovation, it’s time to look closer to home.

One standout among them is Extrudr, an Austrian company producing premium, bio-based filaments, with over half their portfolio derived from renewable materials.

I. The Hidden Side of 3D Printing: Emissions & Health Risks

FDM 3D printing, while convenient and versatile, can release ultrafine particles (UFPs) and volatile organic compounds (VOCs) when filament is heated. Our studies have shown that even popular materials like PLA, ABS, and ASA can emit amount of nanoparticles and VOCs that affect indoor air quality, especially when used in enclosed or poorly ventilated spaces.

That’s why choosing cleaner materials and using effective filtration systems is essential for safe, responsible 3D printing

II. Spotlight on Extrudr: Clean, Sustainable, and High-Quality Filaments

Based in Austria, Extrudr has made a name for itself by producing innovative, eco-friendly filaments that meet the high standards of modern makers and professionals alike. But Extrudr isn’t just about beautiful finishes and reliable prints — it’s about rethinking what filaments can be.

Here’s what makes Extrudr unique:

- A strong commitment to bio-based materials and sustainable production

- Filaments that meet REACH and RoHS standards, ensuring fewer emissions and safer printing

- Transparent communication about material composition and environmental impact

In a world where greenwashing is easy, Extrudr stands as a trustworthy, forward-thinking brand that truly integrates environmental responsibility into product development.

III. Key materials that make a difference

Extrudr offers a wide range of filaments, but a few stands out for their unique value and environmental focus:

- BioFusion: A high-performance, bio-based filament known for its stunning surface finish and strength. A favorite among designers and creators who want both aesthetics and responsibility.

- PLA NX2 MATT : Was the first matt filament on the European market, combining a smooth, ultra-fast finish with high opacity and bio-based material.

- GreenTEC: Developed from renewable raw materials, it combines high strength with biodegradability under industrial conditions. Ideal for functional parts in demanding applications, including the automotive industry.

IV. How alveo3D complements sustainable filament choices

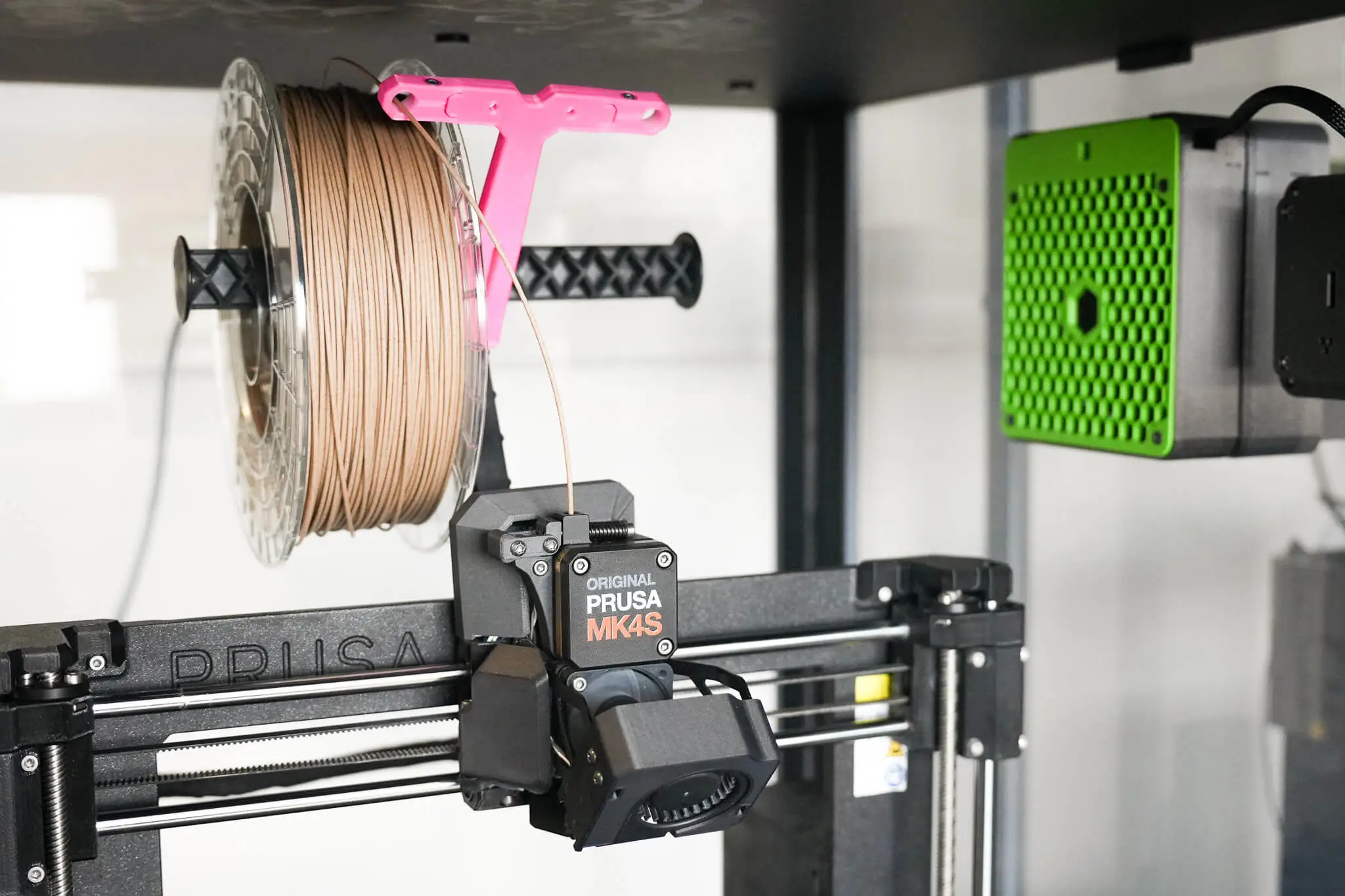

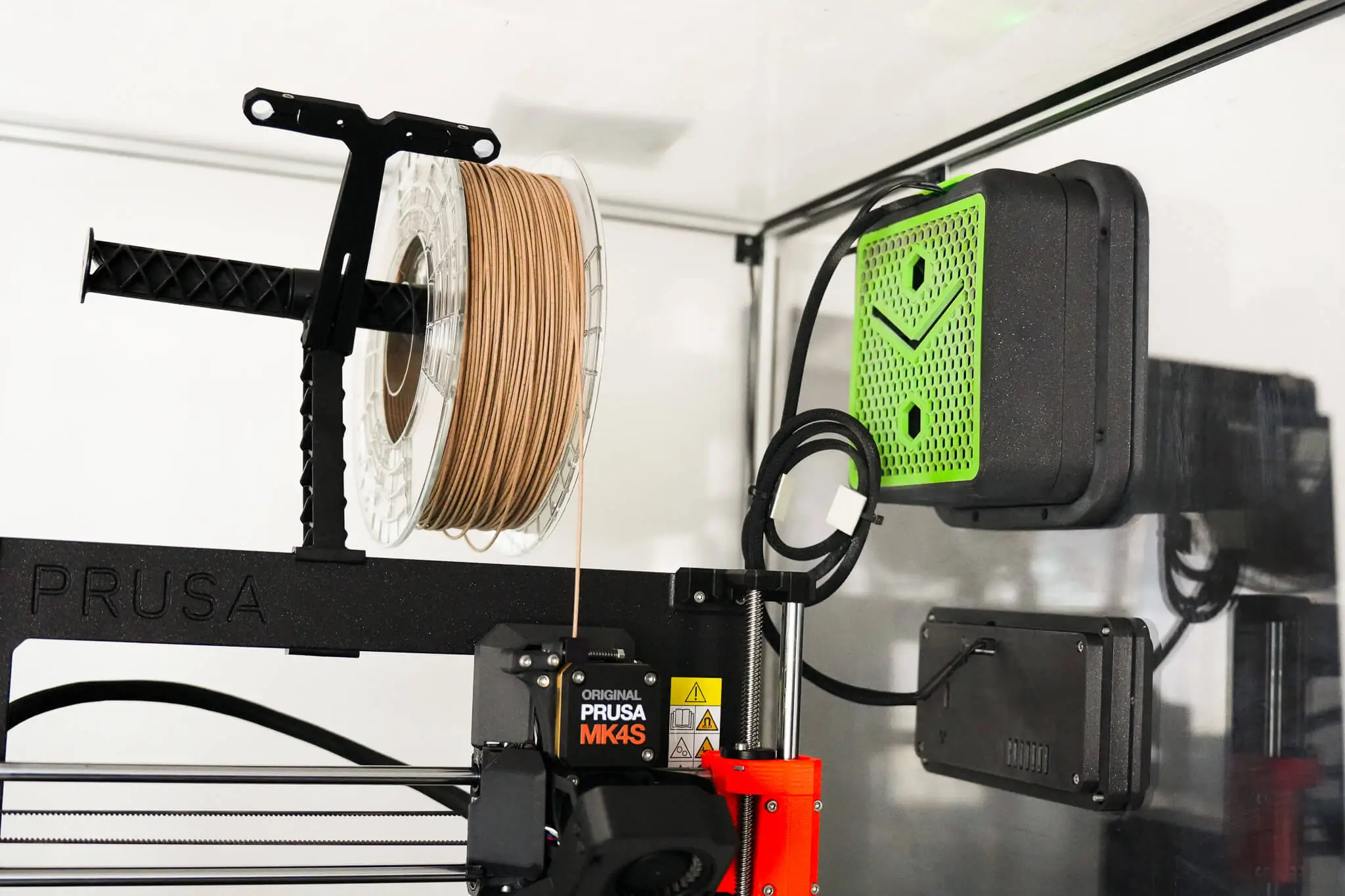

While clean filaments are a big step forward, they’re only part of the equation. At Alveo3D, we develop plug-and-play air filtration systems tailored for 3D printers, helping reduce exposure to harmful UFPs and VOCs during printing.

Our systems are trusted by brands such as Prusa Research, CR3D, and RatRig, and are available across Europe via 3DJake.

By combining high-quality, low-emission filaments like those from Extrudr with professional-grade filtration, users can enjoy better air quality without sacrificing print quality or material choice.

Where to Learn More

- 🔗 Visit Extrudr’s website to explore their full filament range

- 🛒 Shop Alveo3D filtration solutions on 3DJake

- 💡 Follow us on Instagram, LinkedIn for more tips on safe 3D printing

V. Final Thoughts

The future of 3D printing isn’t just about speed, detail, or cost — it’s also about protecting the people behind the printers. We always recommend printing with low-emission materials such as PLA, PETG, or bio-based plastics whenever possible.

If you need to use technical filaments like ABS or ASA, a proper filtration or ventilation system is a must.

Brands like Extrudr show that with the right vision and values, it’s possible to lead the industry in both innovation and responsibility.